A "nut and bolt" inspection is a pre-track / pre-race / start of season tradition. The idea being to check that every fastener underneath your car is present, accounted for and properly torqued. The method can be anything from a cursory look, to a pull on everything critical with a wrench and whatever feels about right, to a check with a torque wrench on everything that can be reached with a torque wrench.

There is a better way. Once you have torqued a fastener to spec, mark it with Torque Seal . This is a lacquer paste that comes in a small tube that you apply to the junction of a fastener and a fitting. It dries to brittle state so that it will crack and fall off if there is any relative motion between the fastener and the fitting.

http://www.aircraftspruce.com/catalog/cspages/f900.php

If your torque seal is intact, all is good.

On a big project, sometimes it is hard to know if you are installing something for good or just for now. It is easy to forget if you have actually torqued a fastener in such cases. Torque Seal applied after the torque wrench is a clear indication that the fastener has been torqued to spec.

We have all laughed at the guy who forgot to torque his wheel nuts and lost a wheel. There but for the grace of god go I. This is "human factors" at work, and it can strike the best of us given the right conditions. Driver's meetings are mandatory. What happens if you get interrupted in your wheel change by a driver's meeting. Are you sure you will remember to torque your wheels when you get back? One trick is to always put your torque wrench on the driver's seat when you start a wheel change. That way you can't drive off without seeing it as a reminder the job isn't quite done.

Other good habits:

- use a checklist and check it off AS YOU DO THE TASKS.

- never leave a job half-done without leaving the work in an obvious state (leave the fastener out rather than putting it in finger tight for example)

- when you restart a job, start back a couple of steps from where you left off

- make a REAL final inspection part of the job

- the right solution for a given task depends on the situation. How familiar are you with the task? How critical is it? Can it be completed without interruption? Will it be completed without interruption?

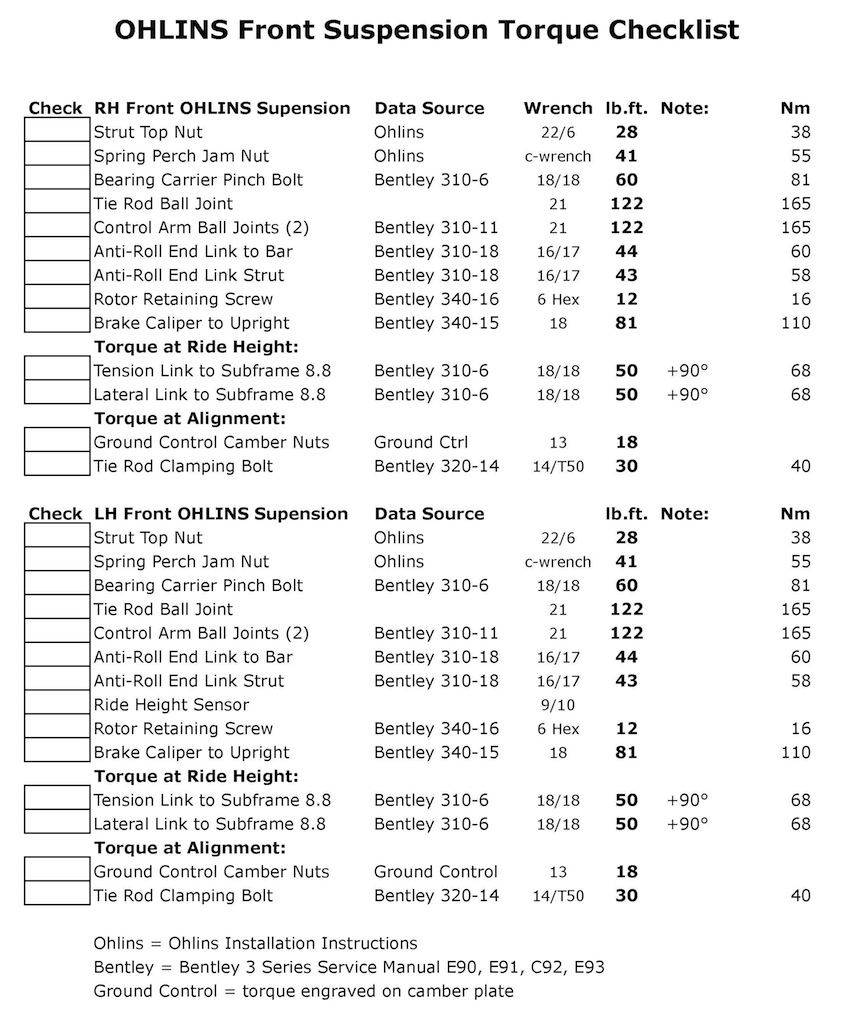

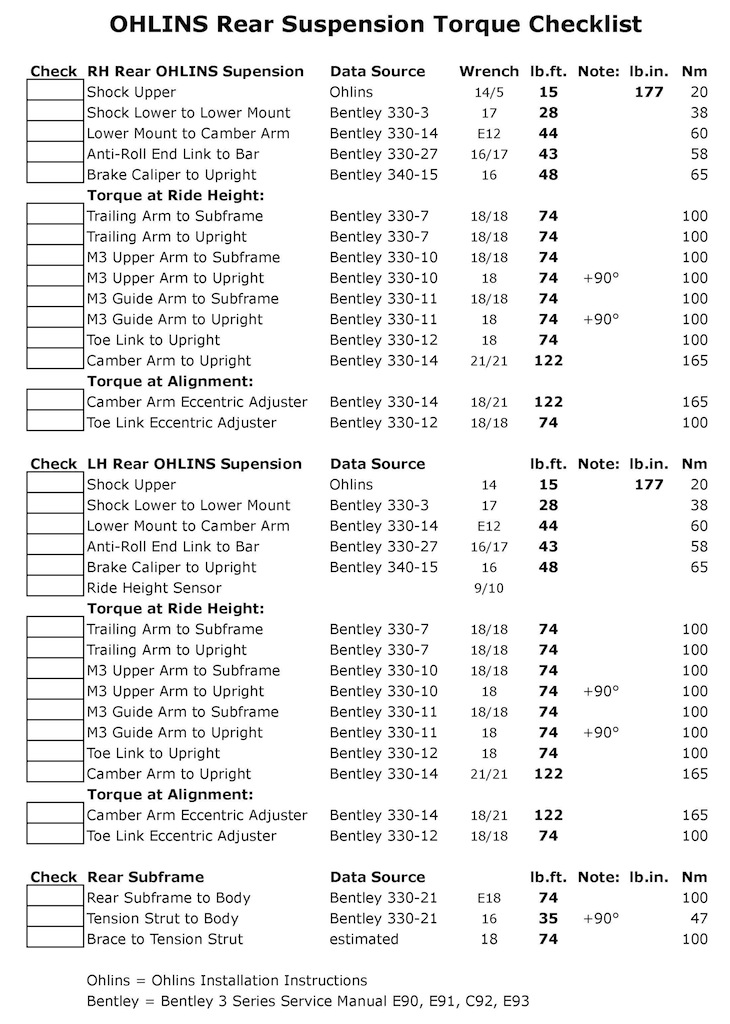

For involved tasks, I like a complete checklist showing all critical tasks, torque specs, manual references and wrench sizes. The job is not done until every box is initialled. Here are a couple of examples for the front and rear suspension installation. Sometimes the official torque value can't be found, but you can always make an educated guess and identify it as such. These lists aren't static - they should be revised with experience and new information.