| 10-01-2012, 03:09 PM | #1 |

|

Lieutenant

269

Rep 470

Posts |

Torque Specs for MTF and Rear Differential Fluid Change?

Does anyone know the torque spec for the bolts when changing the manual transmission fluid and the rear differential fluid on the 1M?

I did a quick search and didn't see anything definitive. Sorry if I missed it. At this point, I just need to know if any of the bolts have a torque spec of less than 25 Nm, which is the spec for the oil drain plug. I'm buying a torque wrench and want to make sure whatever I get covers the range of torque I need for the basic service I intend to do:

|

| 10-01-2012, 03:17 PM | #2 |

|

European Editor

10616

Rep 22,992

Posts |

It is low, 25Nm to 35Nm would be fine. Be sure to OPEN the fill hole first on the trans, before draining the fluid. Just incase you run into any "issues". Having a short 1/4, 8mm "stubby" bit for a 1/4 ratchet worked well for me. You can also use those L-shaped allen keys as well.

The diff inspection hole is a bit tighter. Just use common sense when you open them. You will know how much torque to use - when you open the trans/diff plugs. You won't strip out anything bc the threads are so beefy. ~30Nm should be fine. Btw... wheel bolt torque is 130Nm.

__________________

|

|

Appreciate

0

|

| 10-01-2012, 03:28 PM | #3 | |

|

Thread killer

646

Rep 1,896

Posts |

Quote:

Offhand I do not know the MTF and diff torque specs but would love to know when you find out. |

|

|

Appreciate

0

|

| 10-03-2012, 04:00 PM | #4 | |

|

Lieutenant

269

Rep 470

Posts |

Quote:

Accuracy considerations: Regarding the accuracy of the electronic wrenches, the Snap-on tech guy I spoke with said a couple of interesting things. First, the 2% accuracy figure for the wrench was, he felt, underrated—he said it’s really closer to 1%. Second, in his opinion, he didn’t think it was worthwhile for the type of work I was going to do to pay the premium for a “high accuracy” 1% wrench, which both Snap-on and CDI offer. Decision: After considering the electronic torque wrenches and the electronic “torque + angle” wrenches from Snap-on and CDI (both brands are owned by Snap-on, by the way), I decided to go with the 1002CF3 wrench from CDI. I'm sure there are other great—maybe even better—torque wrenches out there, but I felt pretty good going with Snap-on / CDI.  I decided the “torque + angle” wrenches (Snap-on TechAngle ATECH2FR100A and CDI 1002TAA), while awesome, had more functionality than what I needed and didn’t offer any additional accuracy—only a higher price. I’ll get one of these at a later date if and when I need the “+ angle” functionality. The decision between the Snap-on (Techwrench TECH2FR100) and CDI (1002CF3) electronic torque wrench mostly came down to price—I found the CDI wrench to be less expensive—but there are a few minor differences between the wrenches to be aware of, even though they’re essentially the same wrench in all other respects. The Snap-on wrench has a vibrating handle that tells you when you’ve reached the torque setting, while the CDI wrench has a series of lights that tell you when you’re approaching the torque setting and once you’ve reached it. Both wrenches also have an audible beep when you’re reached the torque setting and an alarm if you’ve exceeded it. Another difference between the two wrenches is that the Snap-on wrench uses AA batteries (there’s a place in the case to store the batteries while the wrench is not in use, which is cool), while the CDI wrench uses CR123 lithium batteries. One other minor difference is that the CDI wrench has a push-button socket release head, whereas it looks like the Snap-on wrench does not. Other than these minor differences, the guy at Snap-on said the quality was the same between the two wrenches. He said he actually preferred the CDI light bar vs. the Snap-on vibrating handle, but that just came down to personal preference. Purchase: I bought the CDI 1002CF3 from Phillips Steel out of Long Beach, California. I found them on Amazon, but wanted a different shipping option than just standard UPS ground, so I contacted them directly yesterday morning. Liz was fantastic to work with and my wrench was shipped later the same day. It should arrive via USPS Priority Mail either tomorrow or Friday. I’ll post pictures when it arrives, but so far I have been very happy with my decision to purchase the CDI 1002CF3 and to order it from Phillips Steel. Final thought: On a somewhat related note, is anyone else finding their regular tools aren’t “good enough” for the 1M? I really must be a marketer’s dream. It’s been less than a year since we picked up our 1M and already I’ve ordered a new floor jack, new jack stands, new ramps, new cleaning and detailing products and—now—a new torque wrench. I had all of these things in my garage/toolbox already. The ramps and jack stands I had didn’t work with the 1M, so getting new ones was justifiable. But with the torque wrench, floor jack and cleaning and detailing products it was just a matter of “not good enough”. I even find myself wondering if the cheap “blue water” windshield washer fluid is good enough for the 1M—or if I should upgrade to something more worthy of the ///M windscreen squirting system.  What a headcase I am! But least I’m a headcase with some awesome new tools… What a headcase I am! But least I’m a headcase with some awesome new tools…Last edited by ///BYU; 10-03-2012 at 04:12 PM.. |

|

|

Appreciate

0

|

| 10-03-2012, 04:05 PM | #5 |

|

European Editor

10616

Rep 22,992

Posts |

You realize when you get around to changing your tran's oil... there is NO WAY a tq wrench is gonna fit between the trans and the car's chassis/tunnel. The clereance is really tight. There is maybe two inches between the trans and body/tunnel.

I bought a special 8mm, 1/4 socket bit and use it on a small 1/4 flexi ratchet. You will see when you change your oil.  For the rear diff, you can use a tq wrench no problem. Btw... you better have a good set of Torx and E-sockets(reverse torx) to work on these cars!  Dack

__________________

|

|

Appreciate

0

|

| 10-03-2012, 04:19 PM | #6 | |

|

Lieutenant

269

Rep 470

Posts |

Quote:

Also, I know that now that I've decided to get one instead of two torque wrenches like ayao did, it won't be long until I need to torque something to < 20 Nm or > 140 Nm.  ...but at least I can find solace in knowing my torque wrench, while useless, has blinky lights and makes beeping noises. ...but at least I can find solace in knowing my torque wrench, while useless, has blinky lights and makes beeping noises.Last edited by ///BYU; 10-03-2012 at 04:26 PM.. |

|

|

Appreciate

0

|

| 10-03-2012, 04:35 PM | #7 | |

|

European Editor

10616

Rep 22,992

Posts |

Quote:

I think you really need two tq wrenches, sorry to tell you. The reason is that most tq wrenches are not so accurate at the "low" or "high" ends of their range. When using them to torque fasteners you should choose a torque wrench that fastener that you are tightening is in the middle of its torque scale/range. For example... the torque wrench I use for my spark plugs (they need to be tightened to 23Nm) is from Gedore (1/4" drive ratchet) and has a tq range of 5Nm to 50Nm. The spark plug's 23Nm spec's fits perfectly in the middle range of its tq scale. For my wheel bolts.... they need to be tightened to 130Nm... I use a Hazet 1/2 tq wrench that has a torque scale of 40Nm to 200Nm. Again that 130Nm fits nicely in the middle range. Dackel

__________________

|

|

|

Appreciate

0

|

| 10-03-2012, 04:38 PM | #8 | |

|

European Editor

10616

Rep 22,992

Posts |

Quote:

For a (VO ?) 1M you should use that orange Rain-X stuff!

__________________

|

|

|

Appreciate

0

|

| 10-03-2012, 04:56 PM | #9 | |

|

Lieutenant

269

Rep 470

Posts |

Quote:

For me it came down to my budget and deciding which was going to be better--two click-type wrenches used in the middle of their range or one electronic wrench used across a broader spectrum of its range. Ideally, I would have been able to get two electronic wrenches, but it wasn't in the budget. Time will tell how happy I am with my decision. Worst case--I realize I made a mistake and sell my torque wrench in near-new condition and buy two wrenches to replace the one I sold. I do think there's merit to having a smaller form factor torque wrench for smaller torques on smaller bolts. That's something I didn't think about. Something about using a 3/8" drive torque wrench that's as long as my arm (okay, it's "only" 17" long but you get the point) with a small socket on the end seems kind of amateurish... My 1M is AW. Milk it is. But only organic milk will do. Last edited by ///BYU; 10-03-2012 at 05:06 PM.. |

|

|

Appreciate

0

|

| 10-03-2012, 09:37 PM | #10 |

|

Thread killer

646

Rep 1,896

Posts |

1. I have torque wrench envy.

2. While I haven't filled the windshield wiper fluid reservoir with unicorn tears, I have spent quite a bit acquiring tools to be able to wrench on the car. Jack, jackstands (Esco!), etc etc. My wife believes I have lost it. |

|

Appreciate

0

|

| 10-04-2012, 11:25 PM | #11 |

|

Lieutenant

269

Rep 470

Posts |

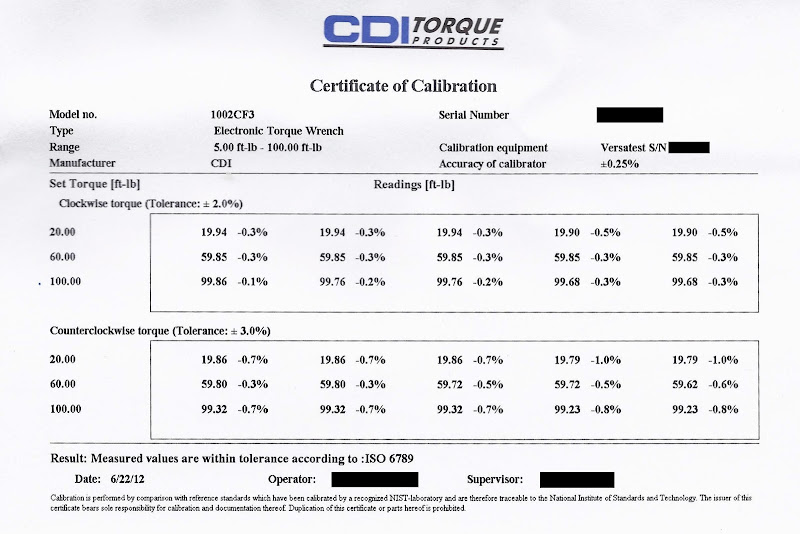

My torque wrench arrived today. It only took two days from So. California to Minnesota via USPS Priority Mail.

Here's the certificate of calibration that came with the wrench. They did five readings each at 20.00, 60.00 and 100.00 ft lb (27.12, 81.35 and 135.58 Nm), both clockwise and counterclockwise.  Last edited by ///BYU; 10-04-2012 at 11:48 PM.. |

|

Appreciate

0

|

| 10-05-2012, 01:59 AM | #12 |

|

Captain

119

Rep 771

Posts

Drives: LBB M2C, VO 1M, GSA 1200

Join Date: Sep 2007

Location: Frozen Tundra

iTrader: (0)

Garage List 2021 BMW X3M Compet ... [0.00]

2019 BMW S1000R [0.00] 2019 M2 Competition [0.00] 2018 BMW 1200 GSA [0.00] 2011 1M Coupe [9.75] |

That's an impressively precise instrument. Especially across a broad torque range.

|

|

Appreciate

0

|

| 02-13-2013, 04:25 PM | #13 |

|

European Editor

10616

Rep 22,992

Posts |

One note for everyone with a torque wrench... when your not using it... you should always have the TQ dial set to "0". In other words IF you are torquing your wheels bolts to 130Nm... don't put the tq wrench back in your tool box set to that spec. Dail it back down to "0". That way you don't keep tension on the inner spring of the tq wrench.

I am not sure how the electronic ones work... but that is always how I store my old school tq wrenches.

__________________

|

|

Appreciate

0

|

Post Reply |

| Bookmarks |

|

|