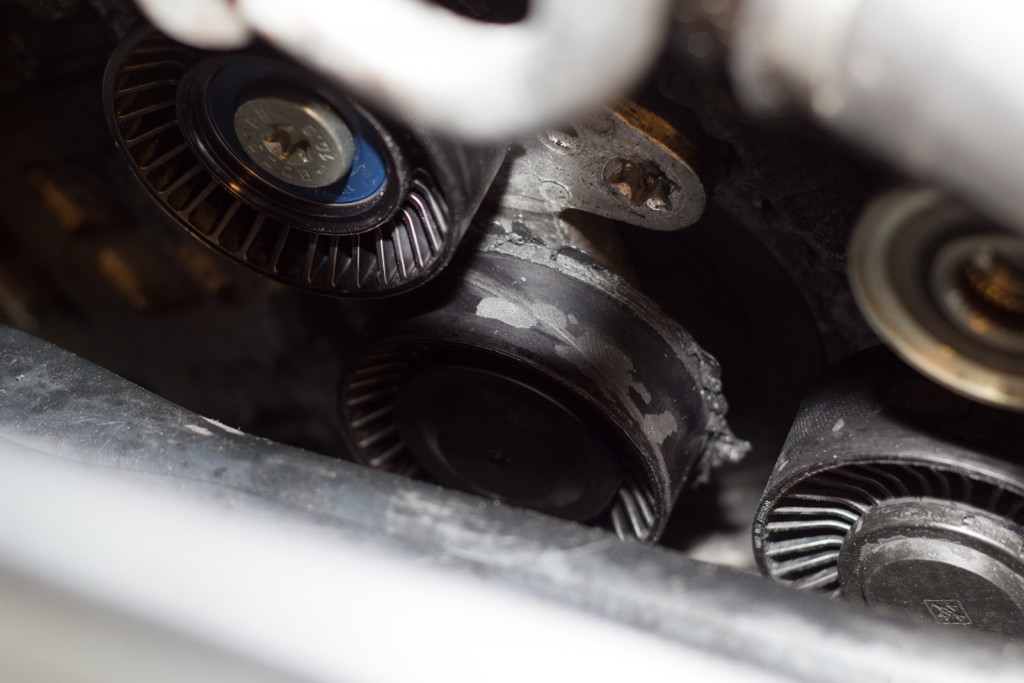

A few weeks later, I started to hear a squeaking noise under the hood. Here is what I found:

Serpentine belt started shredding, so I started replacing stuff. Ordered a new

belt and

tensioner, along with oil filter housing gaskets (

#1 &

#2) because mine were leaking.

Oil filter gaskets going in... what a mess.

I put everything back together and assumed all was good. Wrong. About 50 miles later, the belt started shredding again. This time it started wrapping around the alternator pulley and burnt up the backside of the brand new tensioner pulleys.

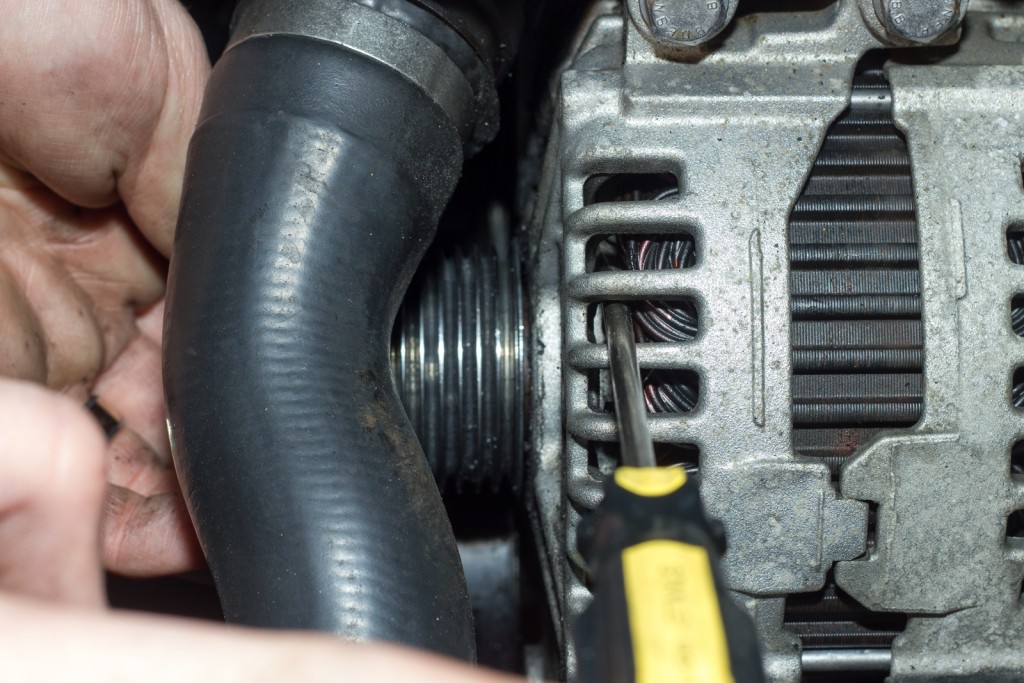

Something was clearly causing the problem. Unsure where to start, I looked at the alternator because the belt wrapped around that specific pulley. The alternator pulley has a sprag clutch inside that allows it to spin one way, but not the other.

This video shows how to test yours. After watching the video, I went out and tested mine. I carefully lodged a screwdriver into the fan to lock it from spinning:

Once the alternator was locked, I tried spinning the pulley by hand in either direction. It was seized and would not move. So, I assumed that was the problem. This time I ordered another new belt, tensioner, as well as an

upper idler pulley, a

lower idler pulley, an

alternator pulley, and an

alternator pulley removal tool.

All of the parts arrived and we installed everything for a second time. The new alternator pulley spun smoothly in one direction as it was supposed to. I thought everything went great and drove the car around for 2 days until the belt shredded

AGAIN! This time the belt started tearing and worked itself off of the pulleys. I was shocked.

I went online and starting reading up on the repeating issue. I saw a lot of discussion about the power steering (PS) pump pulley coming into contact with the subframe. The pulley would hit the subframe and shred the belt or break the pulley. This was caused by worn motor mounts, allowing the motor to flex and sag when accelerating.

However, this issue only affected N54 cars produced up until 04/2008. Apparently BMW addressed the issue at that point. My car was built in 08/2008 so I didn’t think it was my issue, but I took a look anyways. While underneath the car, I noticed that this was

NOT my issue. My PS pulley was

NOT coming in contact with the subframe. But upon further inspection, this is what I noticed:

1 of my PS pump bolts was missing and the other 2 were loose! This is not on the pulley, but on the pump itself. After doing a little more research, a few others reported the same thing. Maybe it’s because the bolts are attached to the oil pan, become coated in oil, and eventually work themselves loose… I’m not sure.

Either way, I removed the 2 loose bolts and found another bolt that fit perfectly in the missing slot. I added a drop of thread-locker to each bolt and reinserted them. I couldn’t find the torque specs, but I torqued them down to 40 ft/lbs.

This time around the tensioner and all pulleys were still in good shape, so I just bought another belt (for the 3rd time). I installed the belt and everything has been running smooth for over 5,000 miles now.

Important Notes:- Check all pulleys the first time around! Make sure there is no play or movement in any of them. They should all spin freely.

- If your N54 was produced before 04/2008, check to see if your PS pulley is coming in contact with your subframe. I’ve read that you can install 335is motor mounts (passenger side, driver side) to fix the problem. You can also notch the subframe.

- If your belt has started to shred, pull over immediately! If the belt works its way around the crankshaft pulley, it can break through the front main seal and even work its way into the timing belt. Best case scenario: the main seal needs to be replaced (oil leak). Even worse, the main seal continues to leak and you run the motor dry. Much worse, the belt causes the motor to jump timing and self-implode. No one wants that, so be sure to check behind the crankshaft pulley for belt fragments. If the belt wrapped around the backside of the pulley, remove it and carefully inspect the front main seal.