I have built a roll bar in to go along with installation of some race seats so I thought I would share some details, since the options for a purchased bar are pretty slim at the moment. This is a bolt-in bar, built to meet the Ontario Time Attack regulations in particular. All tubes are 1.5" x 0.120" DOM with 3/16" floor plates and backing plates. My car has no sunroof. The main hoop has a 5° rake aft, and the rear braces make an angle of 45° to vertical. All up weight is 51 lbs.

Front View

Oblique View

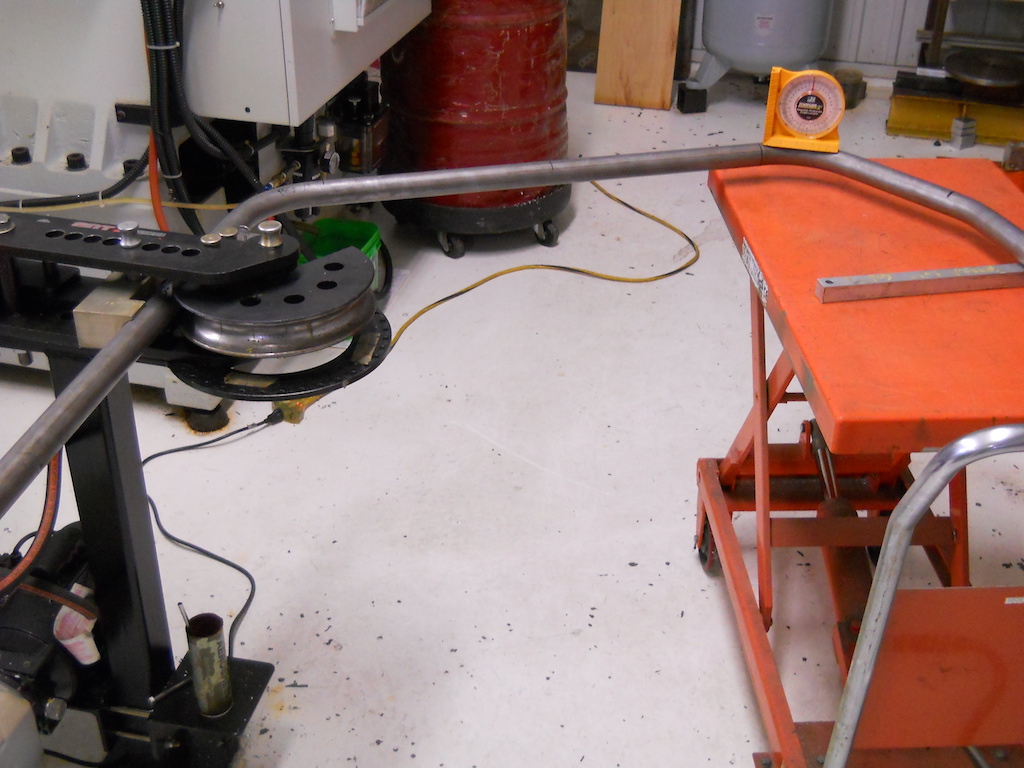

Bending the Main Hoop - bends are 5" CLR

The rear braces on a bolt-in bar must be removable to enable getting the bar into the car. One of the challenges in designing a bar is to choose an appropriate method of making the connection of the brace to the main hoop. I looked to the FIA 2018 Appendix J - Article 253 for inspiration and used a joint similar to their figure 253-39 for that connection.

The pin element welded into the main hoop.

Fitting the pin required drilling the main hoop at compound angles.

The mating saddle fitting on the brace tube.

The connection to the main hoop.

Connection uses a 5/16" socket head cap screw.

The other end of the brace strut uses a bent lug to an existing 12 mm bolt. Not everyone uses this bolt as an attachment point, but my mounting solution allowed me to eliminate a cross bar, with its added weight. The geometry of the welded connection is such that the axis of the strut intersects the shear plane of the mounting bolt. This minimizes bending in the joint under axial loading, and makes for a good welded connection. Cross bars and diagonal bracing of the rear braces is not required by the regulations so I didn't include them to save weight.

Harness guards prevent migration of the harnesses. The harness bar height provides HANS compatibility with my chosen race seats. The guards are anodized aluminum.

Next post, trial fitting ...