I decided to convert the suspension on my dedicated track 135i to fully spherical bearings. There are a few options available but here is how I proceeded:

FRONT TENSION ARM:

I installed a Turner Motorsport TSUE 9080QIS spherical bearing kit on M3 front tension arms I already had installed. The outboard end of M3 and 135i tension arms are both already spherical bearings, but the 135i has a soft fluid filled bushing at the inboard/forward end, while the M3 part has a solid rubber bushing.

Turner has us extract the bushing and press in a housing containing a standard sealed ball joint. Modifying the tension arm is uneventful and starting with either an M3 or a 135i tension arm would get you to the same place

With the spherical bearing installed, it is no longer necessary to torque the forward bolt at ride height as the bearing freely rotates.

FRONT WISHBONE:

135i front wishbones use an inboard rubber bushing vs. the M3 front wishbone’s spherical bearing.

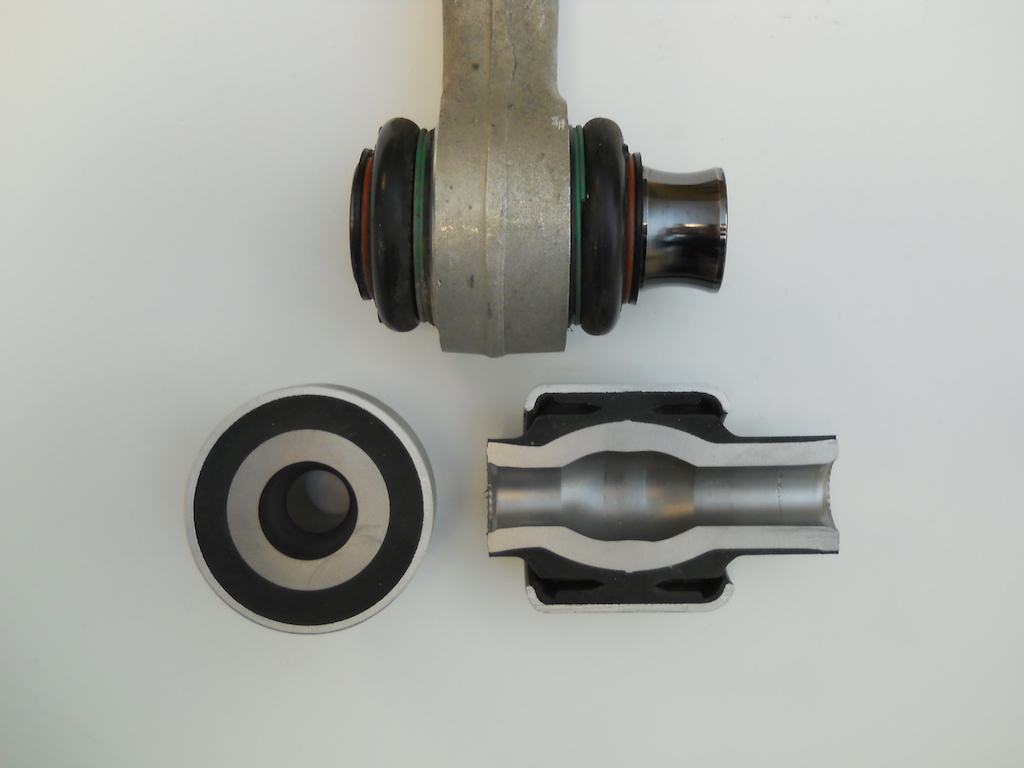

Horizontal and vertical sections through the 135i inboard rubber bushing show its construction vs. the M3 wishbone’s spherical bearing.

The M3 wishbone is also slightly longer than the 135i wishbone, giving a bit more negative camber. I had already installed these parts so no change was necessary.

REAR GUIDE ARM, WISHBONE AND TOE ARM

I elected to use the SPL guide, upper and toe arms. They installed uneventfully and look like really well made parts.

I replaced the camber arm inner rubber bushing with the BimmerWorld kit. Pressing out the bushing and installing the adapter sleeve and spherical bearing are uneventful. The kit looks very well made.

The 135i trailing arm attached to rubber bushings at both ends, one in the upright and the other in the rear subframe. BimmerWorld has a kit to replace these bushing with standard sealed spherical bearings, but here is where things got interesting. With good tooling, extracting the bushings and pressing in the bearings is uneventful.

I found the bearings supplied by BimmerWorld for this purpose to be extremely tight. So much so that the stiction, as measured by hanging a weight on one end of the trailing arm to rotate the bearing at the other end required 10 lbs force to get it to rotate. In contrast, all the other joints would rotate with somewhere between the self-weight of the arm (in the case of the camber arm) and 1 lb hanging at the end of the arm.

In my view 10 lbs (which really means 20 lbs, because both ends of the trailing arm are similarly affected) stiction due to the trailing arm spherical bearings amounts to a suspension bind. This will result inconsistent contact patch forces and will make repeatably corner balancing the vehicle impossible.

I contacted BimmerWorld to investigate and, having just installed a kit in their own shop, they acknowledged that the bearings they supply are tight. In their view, this was not an issue (for a customer car). You can be sure their own race cars don’t bind …

I had deduced that the bearings required are identical to those installed in the 135i rear upper arm. Finding these bearings as stand-alone items is a bit of a challenge, although they are available in the aftermarket in some markets. Finding aftermarket upper arms is easy, as is extracting the bearings, so I tracked down some cheap arms from Rock Auto. Here I learned just how cheap the aftermarket can get. 3 of the 4 arms had bushings pressed to the wrong depth. One had been “reworked”, and the bearing was both crooked and loose in the part. The OD had nonstandard serrations which were presumably part of the rework process. Most importantly to me, the ball joints were just as tight as the ones supplied by BimmerWorld. I got a full refund from Rock Auto and scrapped these, but not before disassembling the ball joints to get spherical targets for my suspension geometry project.

Next, I tried some name brand aftermarket arms (Vaico), which were also too tight, so I ended up returning those.

Now fully committed, I decided to go with OE BMW upper arms, at a very substantial price premium over the aftermarket option. If you have compared OE to aftermarket, you will know that OE BMW bearings really are superior in terms of smooth low-stiction operation. I waited hopefully and received Delphi parts, which I was certainly not going to accept at OE pricing. One more time got me the real thing, and I promptly removed the bearings.

I am happy to report that the stiction levels with the OE bearings are now comparable to all the other joints and my rear suspension now moves without binding.

So, PSA – not all spherical bearings are created equal.

OE BMW / Private Label Crap / BimmerWorld