|

|

|

|

| 07-10-2015, 05:01 AM | #1 |

|

Brigadier General

1493

Rep 3,148

Posts |

M3 LSD in 135i

Just bought myself the M variable differential out of a wrecked low milage E93 M3! Package included the diff, sideshafts and rear section of prop. The guys threw in the hubs for free as they couldn't get them off easily. Hopefully won't be a huge pain getting them off...

Will need to get the rear section of driveshaft cut and welded up to my current shaft, the rest should bolt into my existing subframe and hubs. Will be doing the install myself and getting a driveshaft specialist to do the frakenshaft Will update the thread with the install progress

__________________

|

| 07-12-2015, 08:03 PM | #2 |

|

Private First Class

13

Rep 187

Posts |

Good luck getting the driveshafts out of the hubs. They look rustier than mine.

Make sure whoever you use to press the hubs out only mount the hub flange on the press. Went to 2 places to get mine out. First one damaged the wheel carriers with their 8 tone press as they didn't mount it properly in the press. Second place i went to used a 25ton press and custom gig to get them out as well as soaking them in penetrating fluid over night and using heat. It took about 20Ton of pressure before they eased out. The wheel carriers cost me about $250 each to replace

__________________

2006 E87 130i

M3 front and rear arms, M3 Front and rear ARB , Quaife LSD, BMW performance wheel (non electronic), 135i Brakes, DS2500 pads, Apex wheel studs, Adjustable Bilsteins, API Half cage, Hankook Z221's (track) and Bridgestone RE002's (street) 225's all around |

|

Appreciate

0

|

| 07-12-2015, 08:24 PM | #3 |

|

Major General

898

Rep 6,285

Posts |

Nice score mate, I'm finally getting around to installing my M3 driveline after 2 years of having it in storage!

Did you buy your rear wheel bearings locally? My bearing supplier who we use at work couldn't get me any F A G rear wheel bearings as schaeffler had none on the shelf in Australia... They've had a set sent via express from Germany... Last edited by DR-JEKL; 07-12-2015 at 08:30 PM.. |

|

Appreciate

0

|

| 07-12-2015, 08:30 PM | #4 | |

|

Major General

898

Rep 6,285

Posts |

Quote:

|

|

|

Appreciate

0

|

| 07-12-2015, 10:16 PM | #5 | |

|

Private First Class

13

Rep 187

Posts |

Quote:

Yeah and i didn't notice until i tried to bolt it all back up. The caliper was hitting the disc on one side and the alignment was way out on the other. Then it was weeks later and couldn't prove that the first shop did it. http://www.sydneysuspension.com.au/ was the shop that did it correctly. Try them if Advan cant get them apart.

__________________

2006 E87 130i

M3 front and rear arms, M3 Front and rear ARB , Quaife LSD, BMW performance wheel (non electronic), 135i Brakes, DS2500 pads, Apex wheel studs, Adjustable Bilsteins, API Half cage, Hankook Z221's (track) and Bridgestone RE002's (street) 225's all around |

|

|

Appreciate

0

|

| 07-12-2015, 11:45 PM | #6 |

|

Brigadier General

1493

Rep 3,148

Posts |

Luckily the hub nuts were already loosened by the seller before they shipped it!

I had no luck removing them with a breaker bar due to the hubs rotating as I tried to put torque on them. My electric impact got them off eventually but would have no hope busting a rusted nut torqued down to 400nm, my impact is only rated to about 250nm The axles are still stuck in the hubs, I've got them soaking in WD40 while the gear puller I ordered comes in the mail. Some people have a really hard time getting them out with huge sledge hammers. Fortunately in my case I have the luxury of destroying the hubs if need be, I only need the axle. The only reason why I would preserve them is to maybe sell them on, although I'm not sure that many people are after the hubs. Alternatively I can keep the output flanges and handbrake assembly for conversion to reduce my rear wheel offset by 10mm so I can fit wider wheels. DR-JEKL, why do you need new wheel bearings? Don't you just reuse your existing hubs?

__________________

|

|

Appreciate

0

|

| 07-13-2015, 03:46 AM | #7 | |

|

Major General

898

Rep 6,285

Posts |

Quote:

OK cool thanks for the suggestion, hopefully advan will sort it out  |

|

|

Appreciate

0

|

| 07-13-2015, 03:52 AM | #8 | |

|

Major General

898

Rep 6,285

Posts |

Quote:

The driveline I had came from the UK from a 2010 M3 (I bought it back in 2013) had 20 odd k miles use and 2-3 winters worth of corrosion. Apparently its pretty common to swap wheel bearings out in harsh winter snow conditions due to the amount of corrosion the driveline and undercarriage is exposed to, and Pete had advised I would be best to swap in a fresh set  |

|

|

Appreciate

0

|

| 07-13-2015, 08:01 AM | #9 |

|

Brigadier General

1493

Rep 3,148

Posts |

Wow stuffed bearings after 20k miles, thats pretty brutal. I was pretty surprised at how rusty the hubs on my parts are. The bits came of an E93 M3 vert from NSW (had QLD plates)with 58k kms. Looks worse than my car that has over 130k kms

Are you upgrading your brake master cylinder to accommodate the M3 brakes? They have different part numbers and I read some thread that they might be due to the m3 master cylinder being higher pressure? http://www.realoem.com/bmw/en/showpa...diagId=34_1483 http://www.realoem.com/bmw/en/showpa...diagId=34_1483

__________________

|

|

Appreciate

0

|

| 07-13-2015, 05:37 PM | #10 | |

|

Major General

898

Rep 6,285

Posts |

Quote:

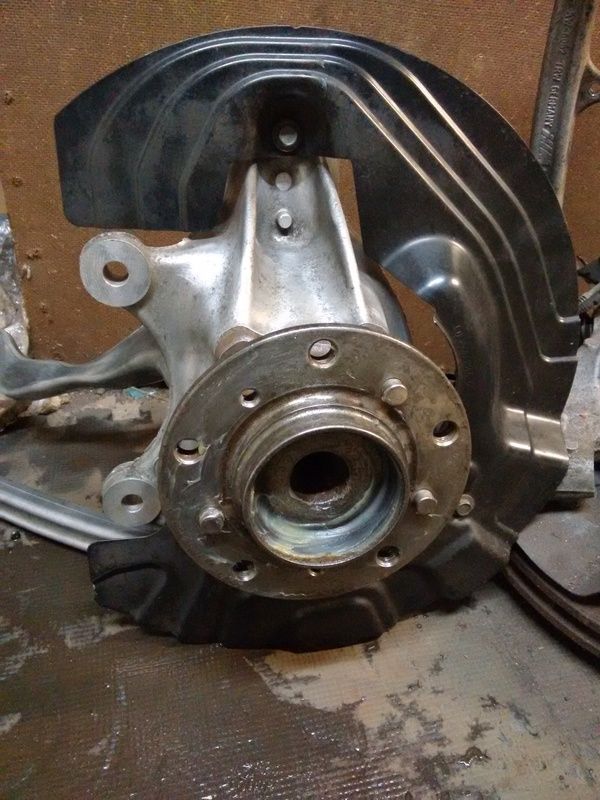

I've spent hours upon hours cleaning all the m3 components:       wheel carrier washed but not scrubbed, wheel hub has been cleaned up:  Wheel hub after rotor removal:  Stage 1 cleaning with some grease to protect the hubs:  Left vs Right:  Aluminium suspension arms:  No Peter said my oem master cylinder and DSC unit shall be fine, touch wood the brakes shall be OK! I cant see a heap of difference between the M3 calipers and the 335i calipers TBH I'm thinking perhaps the major difference is just the larger rotors? Last edited by DR-JEKL; 07-13-2015 at 05:50 PM.. |

|

|

Appreciate

0

|

| 07-18-2015, 06:54 AM | #11 |

|

Brigadier General

1493

Rep 3,148

Posts |

Had a shot at getting the driveshafts out of the hubs with a gear puller. Didn't budge at all and i can see the arms of the gear puller are now deformed! Really crappy puller.

I've ordered a hub puller and going to give it another shot, will need the tool to press out my existing driveshafts out of my car anyway. If it doesn't work I'll have to bring it into a shop to press them out.

__________________

|

|

Appreciate

0

|

| 07-19-2015, 03:31 AM | #12 |

|

Major General

898

Rep 6,285

Posts |

You'll most likely need a driveshaft slidehammer removal tool!

Perhaps go to your local driveshaft shop armed with a bottle of JD and ask them to do it for you? |

|

Appreciate

0

|

| 07-19-2015, 06:06 PM | #13 |

|

Brigadier General

1493

Rep 3,148

Posts |

Ha, I'm just imagining a popeye character who downs a bottle of JD and pops off the driveshafts with ease.

Doing some research on the nominal dimensions of the custom driveshaft that will need to be developed. Ideally I would get a spare propshaft from a wrecked 135i so I can revert the car when it comes to selling, then sell the M3 diff separately. Obviously I will measure this on the car but it would be good to get the nominal dimensions so there is something to work off. These lengths have been obtained via RealOEM: Few things to note: Eurospec n54 135i had flex disc joints to the diff where US spec cars had a single nut coupling (insert nut) for the prop->diff coupling. This obviously alters the total length of the driveshaft. 1M and 135i N55 uses GS6-45BZ gearbox 135i N54 uses GS6-53BZ/DZ gearbox 135i N54 and N55 uses 33107571187 open differential 1M uses limited slip differential 1M driveshaft manual transmission 26107619258 (L=1339MM) (CV joint) 135i n55 driveshaft manual transmission 26107614420 (L=1385MM) (insert nut) 135i n54 driveshaft manual transmission 26107588132 (L=1353MM) (flex disc) 135i n54 driveshaft manual transmission 26107567933 (L=1371MM) (insert nut) 135i n54 driveshaft auto transmission 26107574680 (L=1373MM) (insert nut) 46mm difference between 1M and 135i n55 driveshafts -> 46mm of length due to CV joint on 1M 135i N54 and N55 share the same differential, 135i N55 and 1M share the same gearbox Apply same offset to same style driveshaft for n54: 1371mm-46mm = 1325mm overall length for hybrid driveshaft alternatively work out the difference in gearbox lengths between N54 and N55/1M: 1385mm-1371mm = 14mm apply offset to length of 1M shaft 1339mm-14mm = 1325mm So with 2 seperate measurements giving the same result I am fairly confident that the total driveshaft length needs to be 1325mm. I would use the 135i front section, centre bearing and U joint, and cut off the rear section near the u joint. Then shorten the m3 shaft and weld that onto the 135i shaft. The only thing I am not sure about is how these propshafts are measured. Do they take the flex disc into account? Also the M3 propshaft is slightly recessed into the diff. Will probably need to physically measure the full length of a 135i shaft and an M3 shaft and compare to the quoted dimensions. Unfortunately I only have the rear section of the M3 DR JEKL, do you have the full section of M3 prop?

__________________

|

|

Appreciate

1

AndyW656.50 |

| 07-20-2015, 04:02 AM | #14 | |

|

Major General

898

Rep 6,285

Posts |

Quote:

Cant help you with prop shaft measurements as I haven't needed to do any research on that at all really... No I didnt get a M3 prop, I bought a cheap 740i prop shaft (has the same flange as the M3 diff) and will frankenstein that up with my 335i propshaft |

|

|

Appreciate

0

|

| 08-13-2015, 05:26 AM | #15 |

|

Brigadier General

1493

Rep 3,148

Posts |

Not much of an update, still have not gotten the axles out of the hubs! Been busy iwth other stuff on the car.

I bought another hub tool but didn't have any luck, the new hub tool I bought is a lot better, can really crank on force but its really stuck on there. After cranking on it with a breaker bar with a lot of force, its getting to the point where the forged tool is bending where the bolts mount! Will need to find a place with a 25+ton press to get them out. Meanwhile, I've been sourcing various nuts and bolts. Hate how many single use bolts are on this car! The propshaft bolts are all torque to yield bolts, meaning they deform permanently and stretch to attain maximum clamping force. Got the huge M27 hub nuts and replacement propshaft torx bolts. Needed to get the reinforcement washer plates they bolt onto as well. Still missing the replacement bolts I'll need for the transmission->prop flange but that should be the last parts I'll need for the swap

__________________

|

|

Appreciate

0

|

| 08-13-2015, 06:18 AM | #16 |

|

Major General

898

Rep 6,285

Posts |

That's not a puller, this is a puller!

http://www.ebay.com/itm/SIR-Tools-Re...987580&vxp=mtr That puller you're using is merely using the bolts to pull the hub off, notice how the puller above has a flange which slips over the hub and spreads the force over a greater area behind the hub which will help dramatically along with a much sturdier bolt to apply the force. Buy the bottle of JD go to your local Driveshaft shop and get your GF to bat her eyelids and ask them to remove the hubs for you  Last edited by DR-JEKL; 08-13-2015 at 06:28 AM.. |

|

Appreciate

0

|

| 08-14-2015, 01:38 AM | #17 | |

|

Brigadier General

126

Rep 3,099

Posts |

Quote:

|

|

|

Appreciate

0

|

| 09-30-2015, 08:28 AM | #18 |

|

Brigadier General

1493

Rep 3,148

Posts |

So finally got around to dropping those hubs off at a local driveline shop. They pressed out the driveshafts out the drive flanges. Was a good feeling seeing them finally out of those ugly hubs!

If you look at them, the right side is actually longer than the left side. I wonder if that contributes to any torque steer? The lengths don't differ by much though. Then, as I start cleaning up the splines and threads I notice something very bad: Very very bad  They have not pressed them out squarely on the press and have mushroomed the right side driveshaft. The thread is squished and theres a big bulge. Shit. Pretty pissed, looks like I need a new driveshaft. Will need to go back to the driveline shop and hopefully get my money back  They charged quite a bit of money for this work and they're a driveline specialist so I would have expected them to do this properly. They charged quite a bit of money for this work and they're a driveline specialist so I would have expected them to do this properly.

__________________

|

|

Appreciate

1

|

| 09-30-2015, 07:30 PM | #19 |

|

Brigadier General

1493

Rep 3,148

Posts |

Got my money back this morning from the driveline shop, have already ordered a new driveshaft for $350aud from the US. Bit of a setback but shit happens.

I now have some more information with the installation. I have read a few threads where people have installed M3 diffs but experience humming noises after installation. They probably think their propshaft needs to be balanced but I believe those installations have not observed the proper factory installation methods. I already knew that the drive flange needed to be balanced but after recently acquiring BMW ISTA (latest service manual) I found out there are different type of balancing required depending on the build date of the donor M3 (1Ms all use the same type of balancing). The input flange of the differential is actually balanced, on mine there are two drill holes where they have been balanced. This is probably because the pinion is a helical gear and is not perfectly balanced, so they may fine tune it with the drive flange. Additionally, if you have a certain paint mark on some of the bolt holes you are required to use a washer or bolt (depending on the model year) to balance the diff flange. DR-JEKL installed his diff and has experienced humming noise above 80kph. To tell which type of measures needed to balance the drive shaft, there is some colour coding on the inside of the face of the input flange. If present, you must use a special weighted torx bolt to balance the shaft. If not present, you must use a special weighted washer to balance it out. Attached is the ISTA document that details all this anal information. Alternatively if you know the build date of the donor car, the cutoff was 09/2009 when they transitioned from bolts to washers. This means all 1Ms use torx bolts for balance. You need to look at the coloured mark on the outside of your diff flange to know what type of washer/bolt you need. Washers: http://www.realoem.com/bmw/enUS/show...diagId=26_0202 Torx bolts: http://www.realoem.com/bmw/enUS/show...diagId=26_0202 So for example my car, the donor car was a 2008 with a blue mark on the outer flange and no colour coding on the inside flange. This means I need the 26102284017 (washer for blue mark) to balance my diff flange. Hopefully I should have parts in the next couple of weeks and I can finally start installing. I have decided to swap the parts myself and send out the propshaft to a driveline shop. I debated whether to let a shop install it but there's too many steps involved for me to trust a shop to do it. Some of the things are quite critical and I just don't want any more fuck ups. If I want it done right I'll have to do it myself.

__________________

|

|

Appreciate

0

|

| 10-01-2015, 05:47 PM | #20 |

|

Colonel

171

Rep 2,682

Posts |

Quick comment. I wasn't aware that the M3 diff housing could mount up to the 135i rear subframe. I was under the impression that at least one of the mounting points was different but I could be wrong.

__________________

|

|

Appreciate

0

|

| 10-01-2015, 07:09 PM | #21 |

|

Brigadier General

1493

Rep 3,148

Posts |

Yes it should fit fine, heres a picture of it fitted to a 335i subframe which has the same part number as a 135i:

http://www.e90post.com/forums/showpo...&postcount=322 Pretty cool that hes got a composite driveshaft! Full thread here: http://www.e90post.com/forums/showthread.php?t=321625

__________________

|

|

Appreciate

0

|

| 10-01-2015, 08:27 PM | #22 |

|

Major General

898

Rep 6,285

Posts |

Jeez Vince it sucks they damaged your driveshaft!

I'm pretty sure you could recut the thread with a thread die, and the shaft would still be OK. |

|

Appreciate

0

|

Post Reply |

| Bookmarks |

| Thread Tools | Search this Thread |

|

|